- Monday - Friday: 6:00am - 4:00pm

Global Leader in Precisiton Sheet Metal Fabrication, CNC Machinining, Contract Manufacturing, Powder Coating, Value-add Services

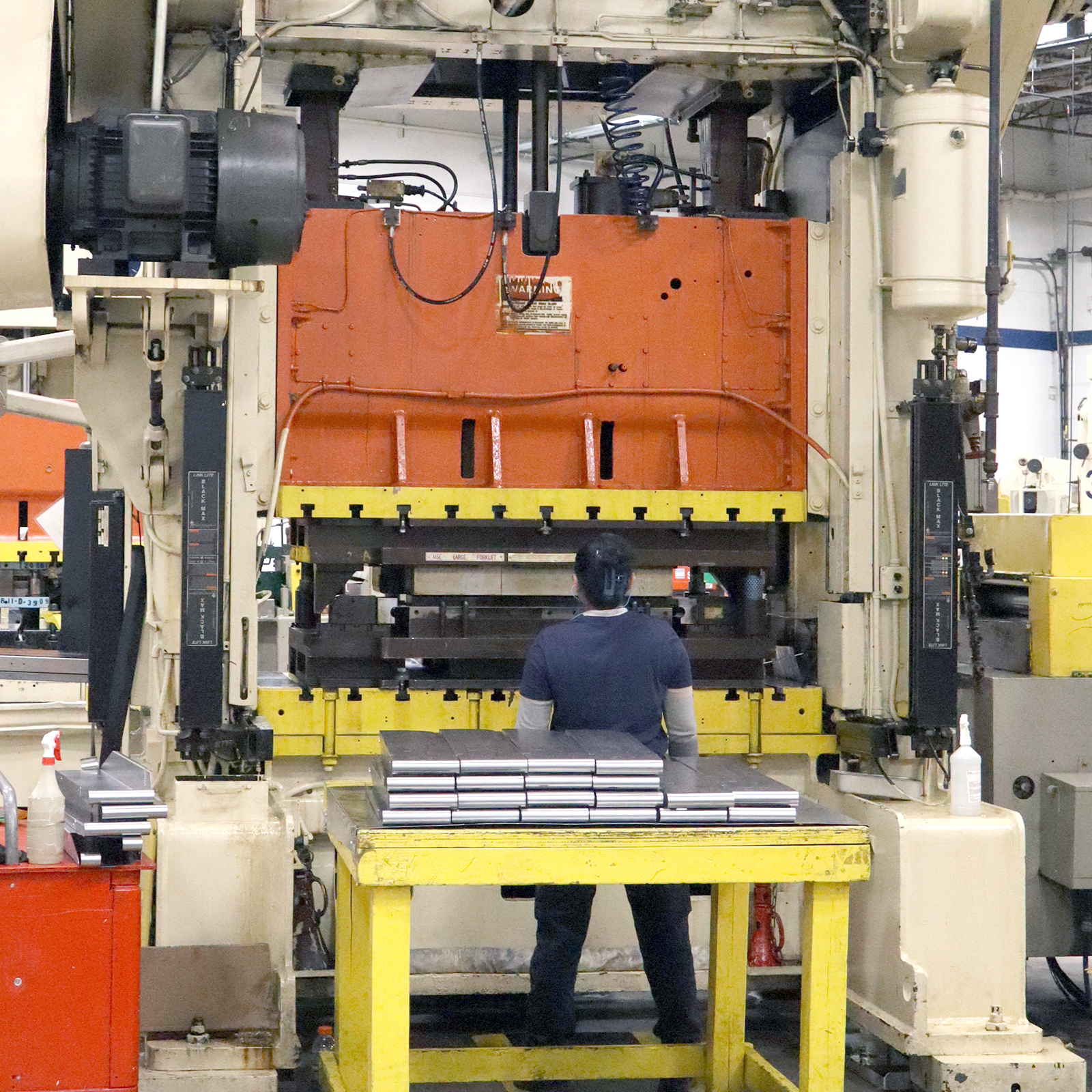

Since the 1940s, Larsen has led the metal stamping industry, serving a wide range of customers and industries.

-

Capabilities 61 Presses (25 to 1000 T)

-

Press bed sizes up to 192” x 55”

-

Services Deburring, tapping, milling, and 100% inspection

Larsen Manufacturing blends technology and experience to deliver consistent, high-quality metal fabrication.

-

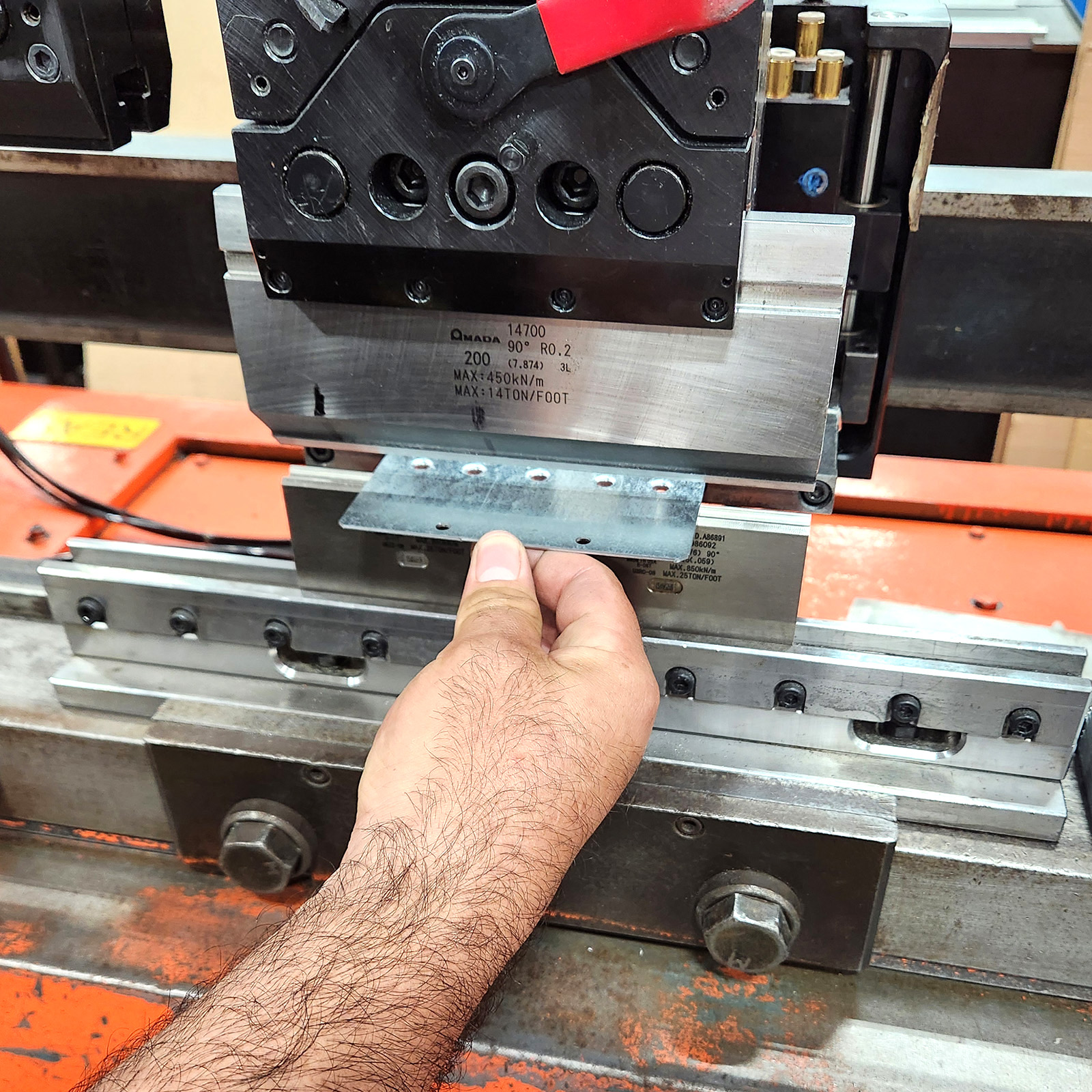

Capabilities Cutting, punching, bending, and forming with Amada lasers and presses

-

Welding, machining, finishing, and assembly to exact specifications

-

Services Secondary fabrication: assembly, MIG/TIG welding, hardware insertion, polishing, grinding, and more

Larsen’s new eco-friendly powder coating service delivers high-quality, contamination-free finishes and supports a complete “Dock to Stock” service.

-

ECO-friendly powder coating system with no iron phosphates

-

Auto-spray capabilities added in 2021

-

Advanced Application Process using virgin powder in a clean, controlled environment

Larsen offers end-to-end contract manufacturing by combining precision metal fabrication with full-scale assembly services.

-

Mechanical and electrical assembly, wiring, testing, and customized packaging

-

Handling sub-assemblies and finished goods for medium to high volume production

-

Expert engineering support for design alignment and sourcing

Larsen offers a full range of welding services, from basic weldments to complex fabrications with multiple welded components. We specialize in:

- MIG, TIG, and Spot/Projection welding for high and low volume projects

- Robotic and manual welding capabilities

- Certified welding team and thorough quality analysis

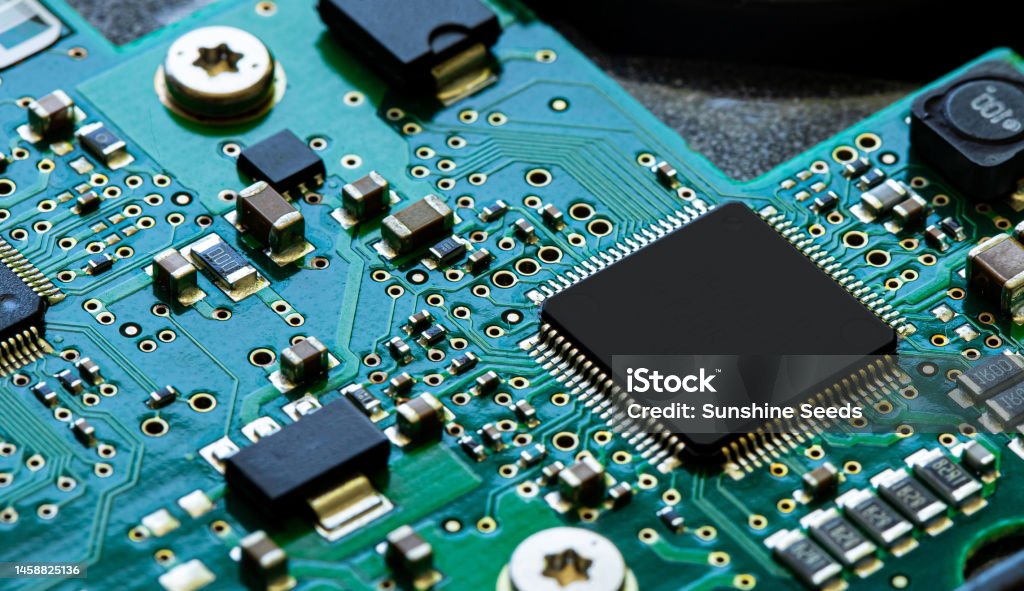

Larsen’s WAND Depaneling System is designed to reduce stress and prevent damage during the separation of populated printed circuit boards (PCBs). Ideal for medium to high-volume PCB separation, it ensures clean and precise results.

-

Eliminates stress and flex, preventing fractured joints and excess burrs

-

12-second cycle time with quick product changeover (under 3 minutes)

-

Features include air/oil power pack, quick change clamping, and safety light curtains

At Larsen, our engineering services enhance your project efficiency through Early Supplier Involvement (ESI) and Design for Manufacturability (DFM) sessions, helping to reduce costs and lead times.

- Early Supplier Involvement (ESI) to streamline project launches and enhance process efficiency

- Design for Manufacturability (DFM) to reduce costs and fix issues during the design phase

- Full-service engineering support for increased convenience and efficiency

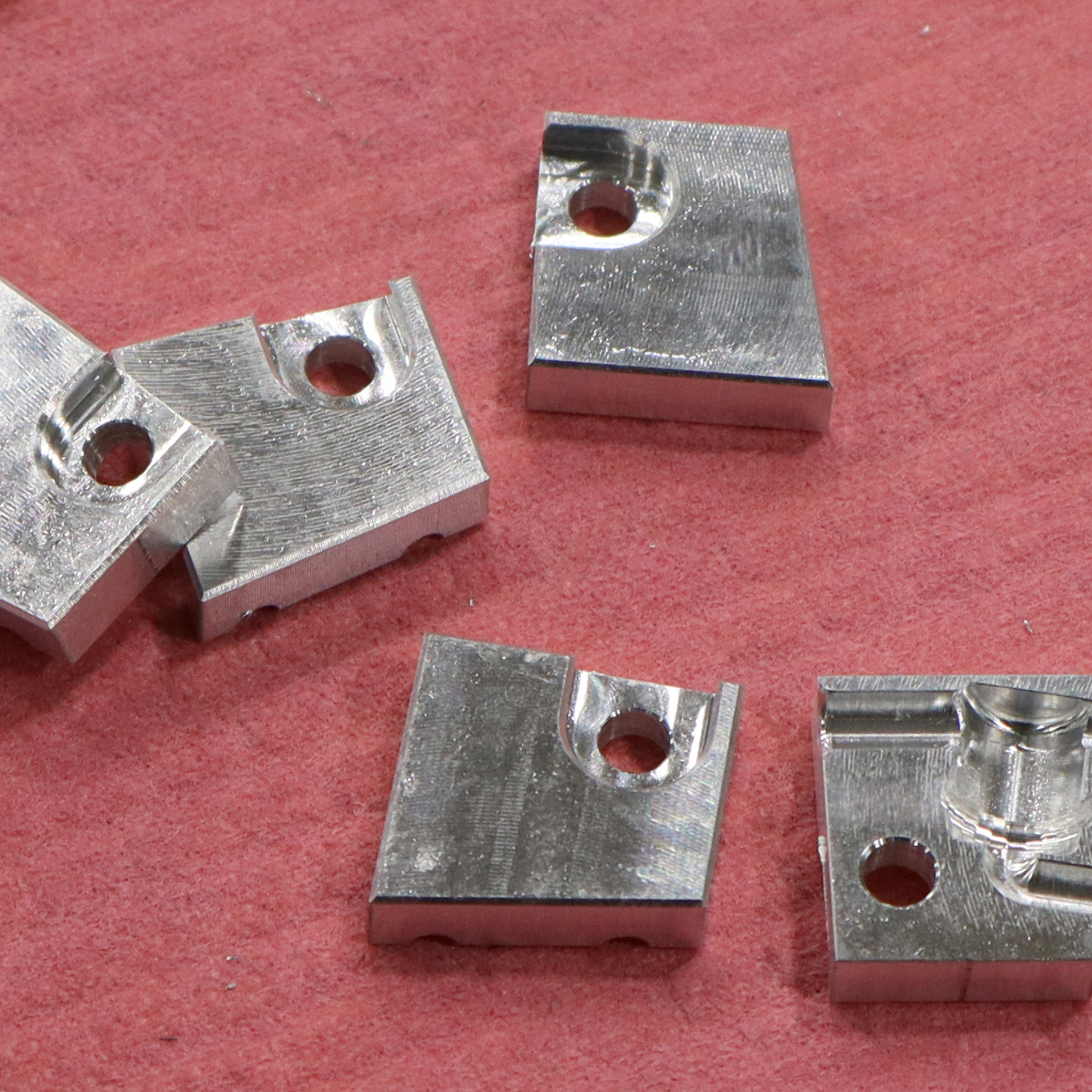

Larsen’s expert technicians ensure rapid and efficient product development through our advanced prototype cell, guaranteeing high quality and a smooth transition into production.

- Expert technicians for fast and efficient prototype development

- Early Supplier Involvement (ESI) to ensure parts meet exact specifications

- Prototyping for certainty in production and improved product quality

Since the 1940s, Larsen has led the metal stamping industry, serving a wide range of customers and industries.

- Expert technicians for fast and efficient prototype development

- Early Supplier Involvement (ESI) to ensure parts meet exact specifications

- Prototyping for certainty in production and improved product quality

Larsen Manufacturing blends technology and experience to deliver consistent, high-quality metal fabrication.

- Expert technicians for fast and efficient prototype development

- Early Supplier Involvement (ESI) to ensure parts meet exact specifications

- Prototyping for certainty in production and improved product quality

Larsen’s new eco-friendly powder coating service delivers high-quality, contamination-free finishes and supports a complete “Dock to Stock” service.

- Expert technicians for fast and efficient prototype development

- Early Supplier Involvement (ESI) to ensure parts meet exact specifications

- Prototyping for certainty in production and improved product quality

Larsen offers end-to-end contract manufacturing by combining precision metal fabrication with full-scale assembly services.

- Expert technicians for fast and efficient prototype development

- Early Supplier Involvement (ESI) to ensure parts meet exact specifications

- Prototyping for certainty in production and improved product quality

Larsen offers a full range of welding services, from basic weldments to complex fabrications with multiple welded components. We specialize in:

- Expert technicians for fast and efficient prototype development

- Early Supplier Involvement (ESI) to ensure parts meet exact specifications

- Prototyping for certainty in production and improved product quality

Larsen’s WAND Depaneling System is designed to reduce stress and prevent damage during the separation of populated printed circuit boards (PCBs). Ideal for medium to high-volume PCB separation, it ensures clean and precise results.

- Expert technicians for fast and efficient prototype development

- Early Supplier Involvement (ESI) to ensure parts meet exact specifications

- Prototyping for certainty in production and improved product quality

At Larsen, our engineering services enhance your project efficiency through Early Supplier Involvement (ESI) and Design for Manufacturability (DFM) sessions, helping to reduce costs and lead times.

- Expert technicians for fast and efficient prototype development

- Early Supplier Involvement (ESI) to ensure parts meet exact specifications

- Prototyping for certainty in production and improved product quality

Larsen’s expert technicians ensure rapid and efficient product development through our advanced prototype cell, guaranteeing high quality and a smooth transition into production.

- Expert technicians for fast and efficient prototype development

- Early Supplier Involvement (ESI) to ensure parts meet exact specifications

- Prototyping for certainty in production and improved product quality

Larsen Catalog

Make sure to get our full catalog that contains all of the information in one consolidated document.

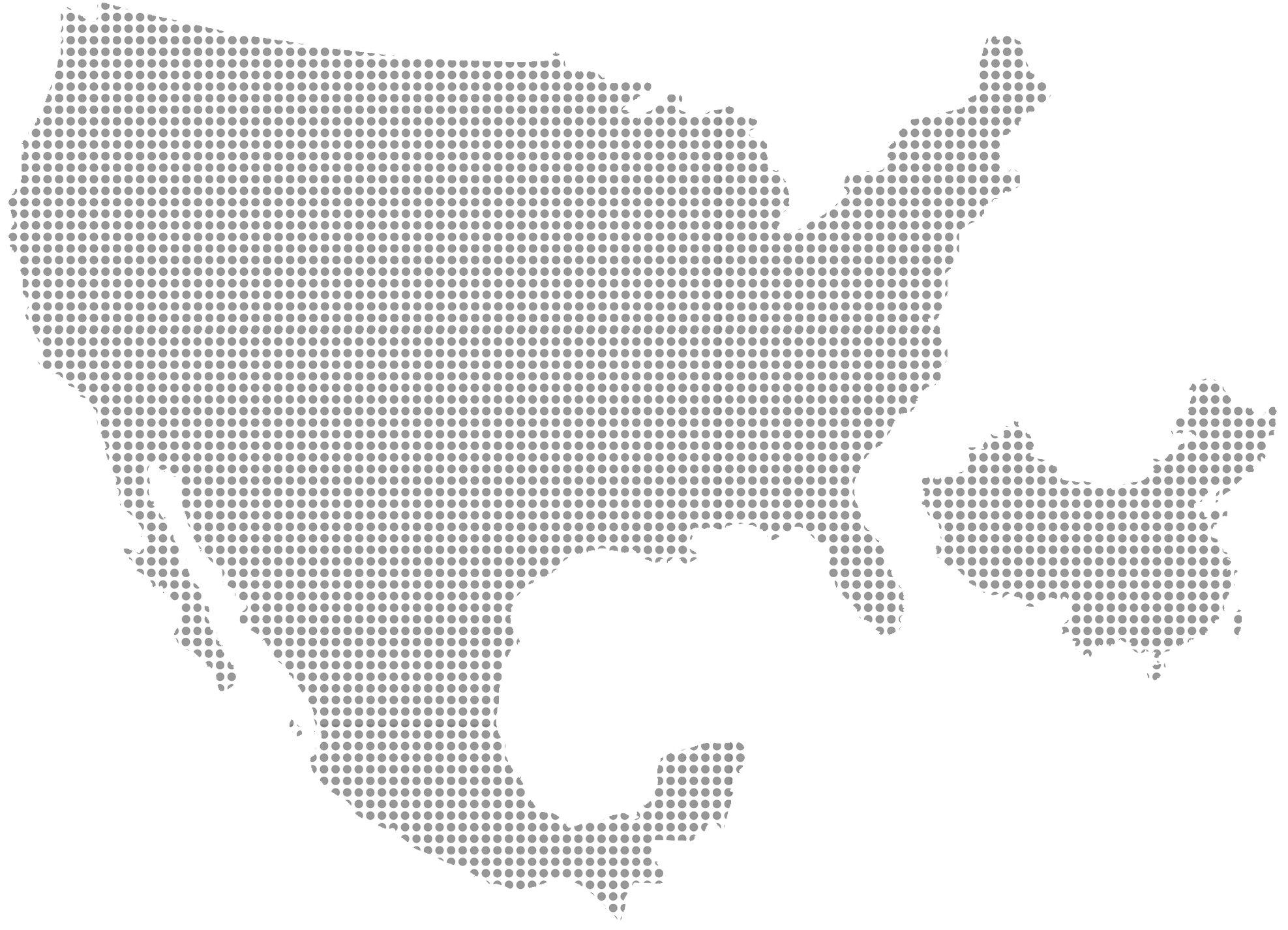

Locations

Mundelein

Stamping, Welding and Assembly Fabrication, Welding and Assembly Precision Machining

Value Add, Powder Coating, Assembly Wearhouse

El Paso

Stamping & Assembly Wearhouse

Brownsville

Stamping & Assembly Assembly

Mexico Teritories

Chihuahua

North East

Center “Bajio”

Pacific

South Centra

Corporate Headquarters

Corporate Headquarters

Corporate Headquarters

Corporate Headquarters

Corporate Headquarters

Corporate Headquarters

Corporate Headquarters

Corporate Headquarters

Corporate Headquarters

Corporate Headquarters

El Paso

El Paso

Chihuahua

Chihuahua

Brownsville

Brownsville

North East

North East

South Centra

South Centra

Pacific

Pacific

Centre "Bajio"

Centre "Bajio"

China

China

Quality

Larsen Manufacturing is committed to providing high quality parts that exceed our customer’s expectations. We achieve this by deploying tight quality systems that ensure consistency and repeatability

- ISO 9001:2015 All Facilities

- IATF 16949:2016 Mundelein Facility

- IATF 16949:2016 El Paso Facility

- ISO 14000 Pending

Who We Serve

Larsen Manufacturing proudly serves a diverse group of customers spanning

thousands of different applications.

Join the Larsen

Manufacturing Team

Larsen is a great place to work. Our success is directly supported by the dedicated and talented staff that continues our tradition of quality.

If you’re a team player with a can-do attitude, and superior workmanship, we can’t wait to hear from you!